FRP Structural Sections

Categories

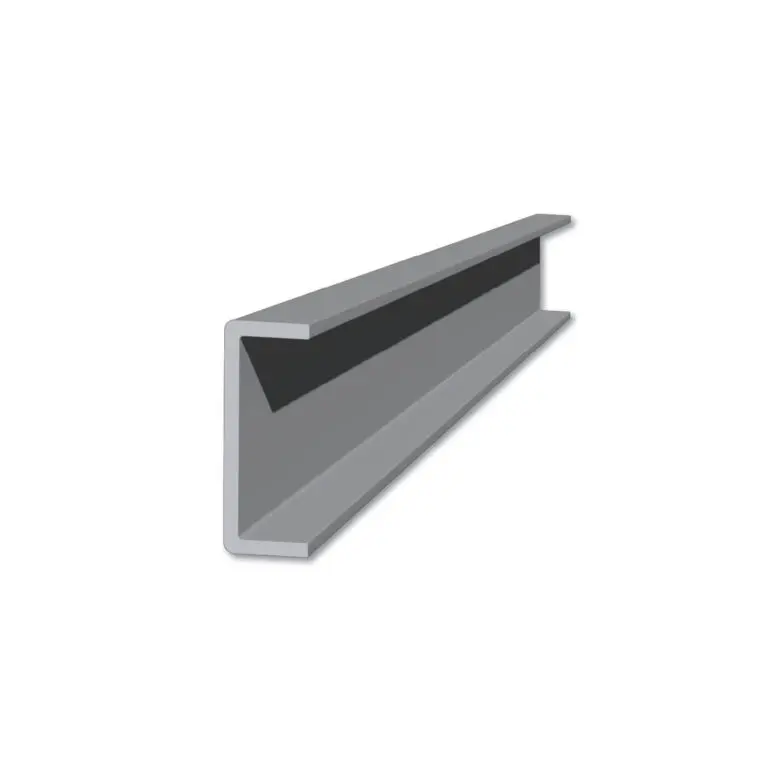

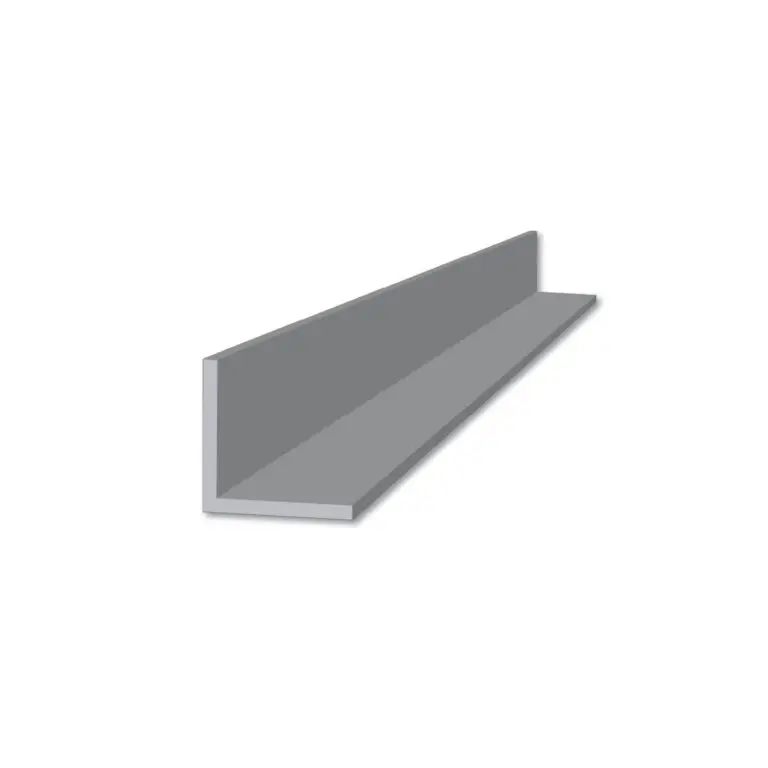

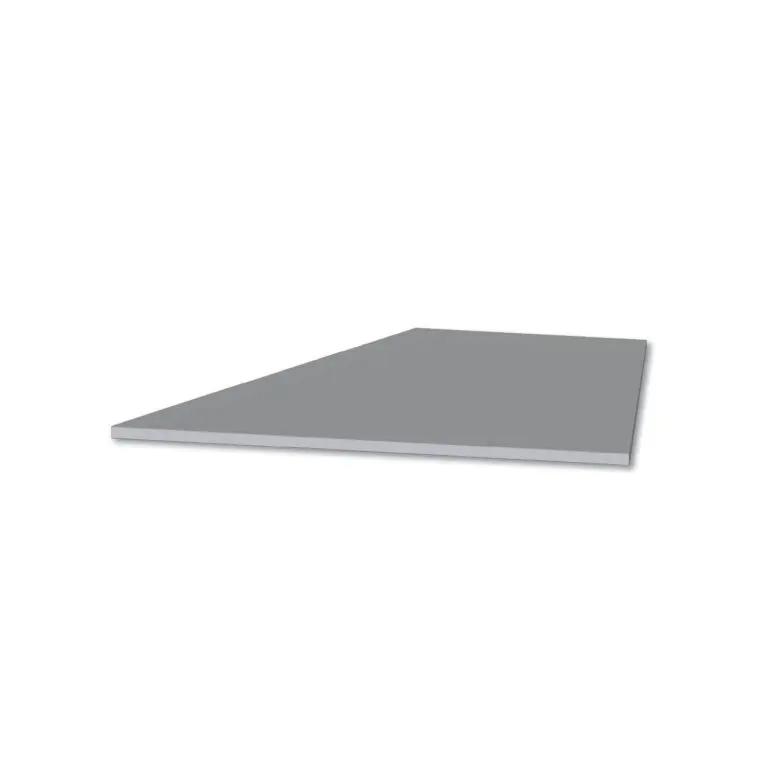

FRP Structural Sections

FRP structural sections are innovative, high-performance alternatives to traditional building materials, such as steel, aluminium, or wood. Engineered to withstand some of the toughest environments, these lightweight yet robust materials combine durability with design versatility.

Manufactured through a pultrusion process, FRP structural sections offer unmatched strength, corrosion resistance, and ease of installation, making them a superior choice for various industrial and commercial applications.

Benefits

Benefits of FRP Structural Sections

FRP structural sections outshine traditional materials thanks to their unique advantages, which include:

Corrosion Resistance

High Strength-to-Weight Ratio

Non-Conductive

Low Maintenance

Sustainability

Technical Specifications

Here are some key technical properties that make FRP structural sections exceptional:

Isophthalic resin as a standard, with options for vinyl ester for enhanced performance.

Stock lengths of 5.8m, with custom lengths available up to 11.8m.

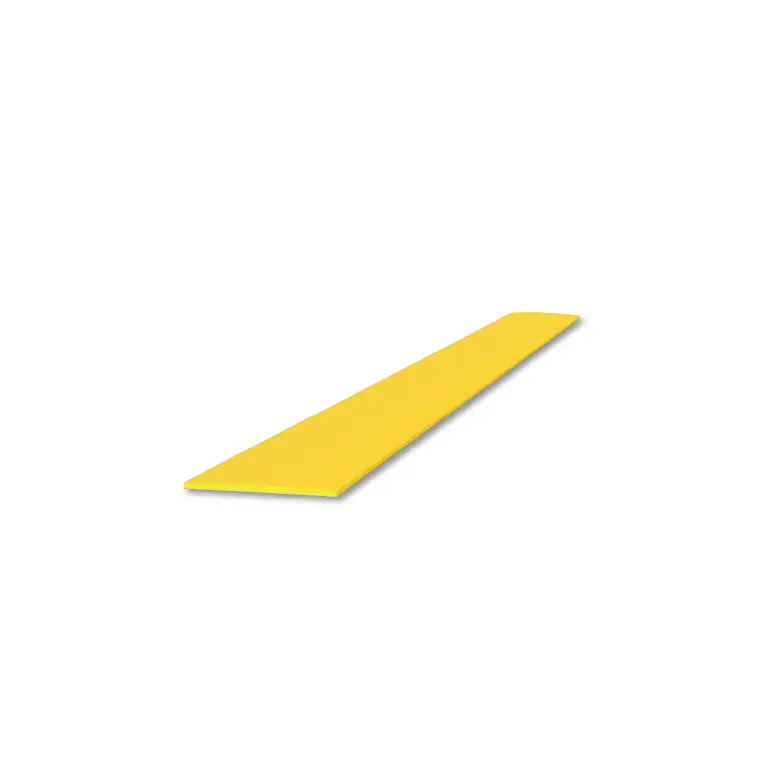

Standard in Telegrey & Window Grey; customisable with any RAL colour for orders exceeding 100m.

Resistant to harsh environmental elements, including chemicals and moisture.

Increases installation efficiency without compromising strength.

Tailor FRP Structural Sections to Your Project

To meet the specific requirements of diverse projects, FRP structural sections can be tailored with the following options:

Applications

Applications and Use Cases

FRP structural sections are versatile and widely utilised across industries. Some typical applications include:

Construction

Marine Industry

Industrial Safety Access

Infrastructure Projects

Telecommunications

Resources

FRP Structural Sections Downloads

At GRP Australia, we’re committed to supporting the success of your project. Explore our resources for more information about our FRP structural sections:

FAQs

What are FRP structural sections commonly used for?

FRP structural sections are widely used in construction projects, such as platforms, walkways, and industrial structures. They are preferred due to their high strength, corrosion resistance, and lightweight properties.

How does the strength of FRP structural sections compare to steel?

FRP structural sections provide comparable strength to steel but are significantly lighter, easier to handle, and resistant to rust and corrosion. This makes them ideal for applications in moist or chemical environments.

What factors should be considered when selecting an FRP profile?

When choosing an FRP structural profile, consider the load requirements, environmental conditions (such as exposure to chemicals, moisture, or UV), the desired span length, deflection limits, and installation constraints. Refer to GRP-GU-01 Structural section design guide for further details.

What fabrication processes are recommended for FRP structural sections?

FRP structural sections can be cut, drilled, and machined using standard carbide-tipped or diamond-coated tools. It’s essential to use tools with dust extraction systems to minimise airborne particles, as FRP dust should not be inhaled. Always wear appropriate personal protective equipment (PPE), including masks, gloves, and eye protection. For best results, make clean, precise cuts and avoid excessive force, which can cause splintering.

What are the best practices for joining FRP structural sections?

Common joining techniques for FRP include mechanical fastening (using stainless steel or non-corrosive bolts and screws), adhesive bonding with structural epoxy or polyurethane adhesives, and a combination of both for added strength. Pre-drilling is advised to prevent cracking, and where possible, oversized holes with washers are recommended to accommodate thermal expansion. For load-bearing joints, refer to GRP-GU-01 Structural section design guide for further details.

How do I ensure the long-term performance of FRP joints?

To maintain joint integrity over time, use corrosion-resistant fasteners, regularly inspect connections for signs of wear or loosening, and re-torque bolts as needed. For adhesive joints, follow recommended curing times and environmental conditions during application. Protective coatings or sealants may be used in harsh environments for additional durability.

Do FRP structural sections need to be painted?

Yes, if FRP structural sections are exposed to direct sunlight, it is recommended to apply a UV-resistant paint or protective coating. Prolonged exposure to ultraviolet (UV) radiation can degrade the surface resin & leads to discoloration. A suitable coating preserves the appearance and extends the service life of the FRP sections, especially in outdoor applications. For installations not exposed to sunlight, painting is generally optional but may be used for identification or aesthetic reasons.

Unlock the Potential of FRP Structural Sections for Your Project

FRP structural sections are the smart, sustainable choice for forward-thinking builders and designers. Whether it’s for industrial, commercial, or residential applications, FRP structural sections provide extraordinary benefits that ensure long-term reliability and minimal maintenance.

Contact us today for expert advice from our specialists, to check current stock availability, or to request a customised quote.