FRP Handrails

Categories

FRP Handrails

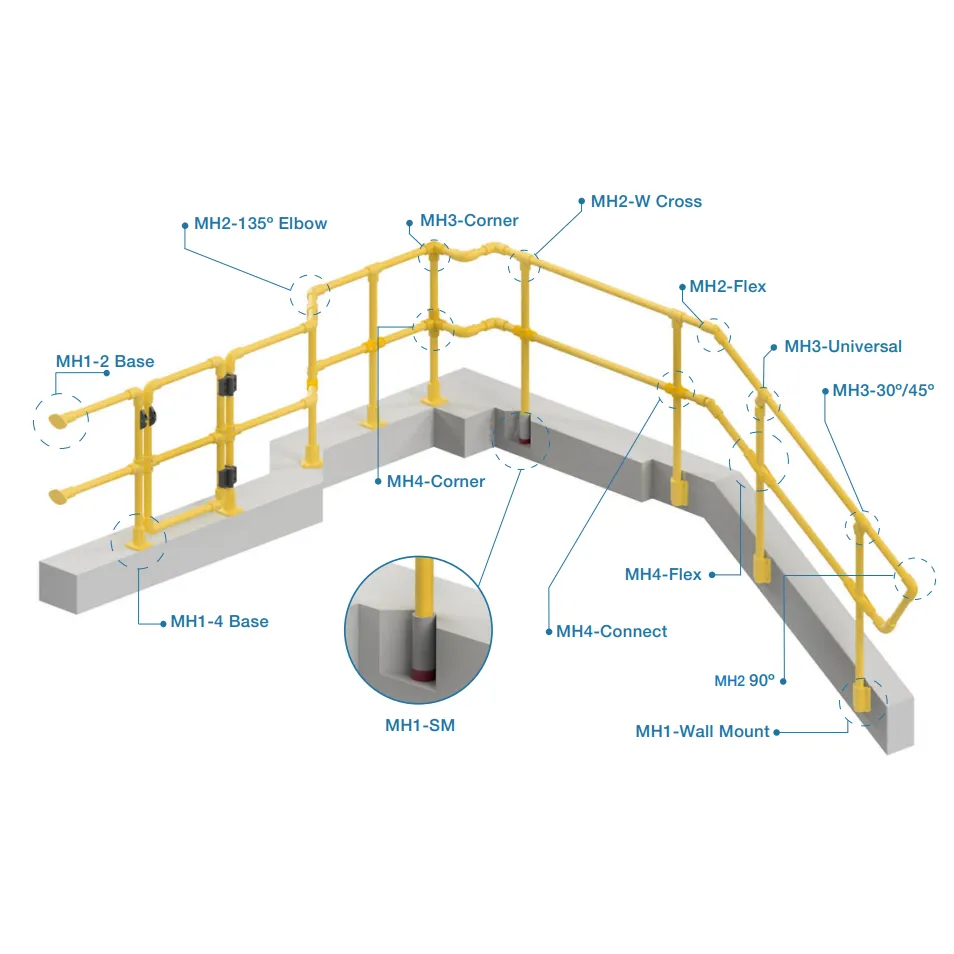

The FRP modular handrail system uses round tube (RT50x5) made from premium vinyl ester resin which forms the top rail, knee rail and stanchions. The rails and stanchions are connected using BMC composite fittings which are fire retardant, non-corrosive and contain UV inhibitors. The fittings are clamped together with stainless steel fasteners provided by GRP Australia. The standard stock colours are yellow RAL 1003 & light grey RAL 7047.

The modular handrail system has been designed and laboratory tested to be compliant with the requirements of AS 1657-2013. The minimum design requirements for FRP Modular Handrail have been set out in the modular handrail brochure. Please refer to the GRP Australia Modular Handrail Installation Guide for fabrication procedures and requirements

Resources

FRP Handrails Resources

FAQs

What makes FRP handrails preferable over metal handrails?

FRP handrails are non-corrosive, lightweight, and non-conductive. They are ideal for environments where exposure to chemicals or electricity is a concern. Additionally, they require minimal maintenance over their lifespan.

Can FRP handrails withstand heavy loads and impact?

Yes, FRP handrails are designed to provide excellent mechanical strength and can withstand significant loads and impacts, making them suitable for industrial and commercial applications.

Are FRP handrails easy to install?

FRP handrails are lightweight and modular, allowing for quick and straightforward installation. Their design minimizes the need for heavy tools or specialized equipment during assembly.

Do FRP modular handrails require painting?

FRP modular handrails do not require painting for structural performance, but if they are installed in areas exposed to direct sunlight, it is highly recommended to apply a UV-resistant paint or protective coating. This helps prevent surface resin degradation and discoloration caused by ultraviolet (UV) exposure, extending the handrail’s service life. Painting may also be used for identification or aesthetic purposes in interior or shaded installations where UV exposure is not a concern.

What are the best techniques for joining FRP modular handrail sections?

The most common joining methods for FRP modular handrails include mechanical fastening—using corrosion-resistant bolts, screws, or rivets—and adhesive bonding with structural epoxy or polyurethane adhesives. For mechanically fastened joints, pre-drilling is advised to prevent cracking of the material, and using oversized holes with washers helps accommodate thermal expansion. In critical applications, mechanical and adhesive methods can be combined for added strength and durability.

What is the recommended spacing between stanchions for FRP modular handrails?

For optimal structural integrity and compliance with typical design standards, it is recommended that stanchions (vertical posts) for FRP modular handrails be spaced at intervals of 1800mm (1.8 metres) unless otherwise specified by the project engineer. This spacing provides robust support while optimising material use and ease of installation.

Contact GRP Today

Discover how GRP Australia can bring your ideas to life with cutting-edge FRP design and engineering tailored to your needs.

Contact us today to explore what’s possible!