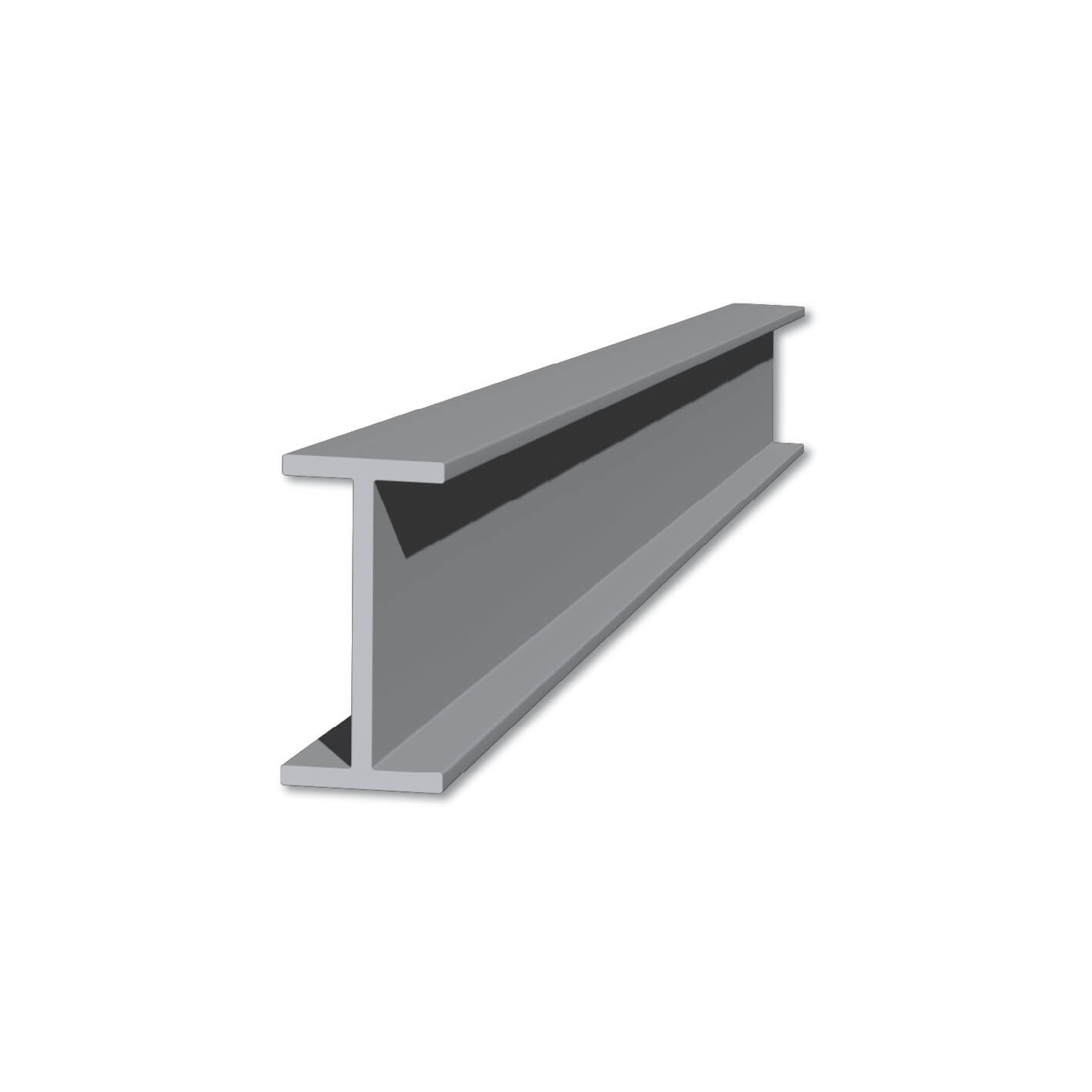

FRP I Beam

Our FRP (Fibre Reinforced Polymer) I Beam Structural Sections are a robust and efficient alternative to traditional steel, aluminium, or timber I beams. Engineered for superior safety, excellent load-bearing performance, and a streamlined profile, these FRP I beams are ideal for structural frameworks, fabrication, and cladding—particularly where long-lasting reliability and performance are required in tough Australian environments.

Key Features & Benefits

- Corrosion Resistance: Like all FRP products, our I beams are immune to rust and corrosion caused by moisture, chemicals, or saltwater, making them a smart choice for coastal, industrial, and chemically aggressive locations.

- Lightweight Construction: Considerably lighter than steel, FRP I beams are easy to handle and install, reducing labour costs and enhancing safety during transport and assembly.

- Outstanding Strength-to-Weight Ratio: Despite their reduced weight, these I beams deliver exceptional structural strength and load-bearing capacity, meeting the demands of various applications.

- Electrical & Thermal Insulation: Naturally resistant to electricity and heat, FRP I beams improve safety for electrical works and installations exposed to extreme temperatures.

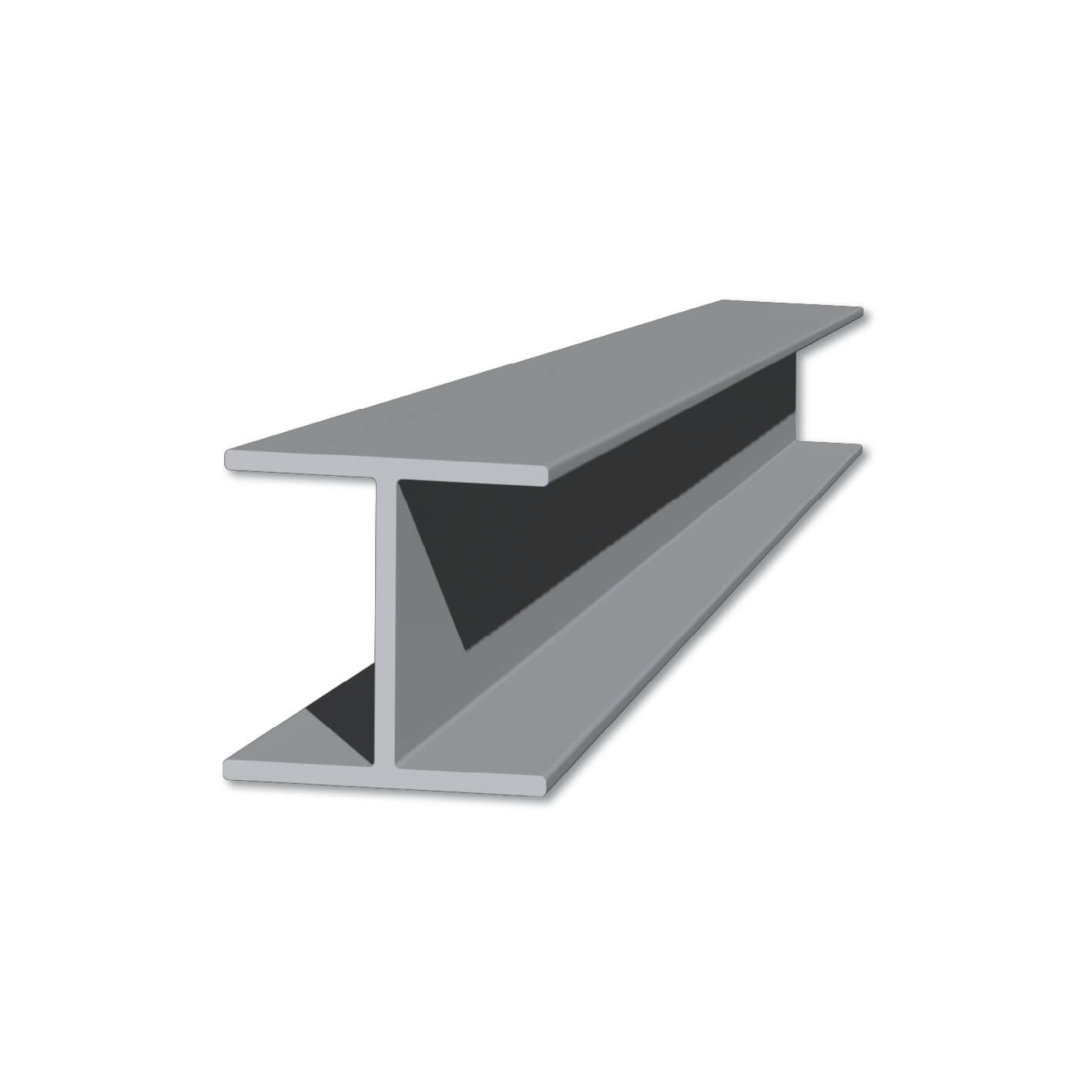

- Safe, Clean Profile: The I beam configuration offers smooth edges and surfaces, reducing snag and injury risks while presenting a polished, professional appearance—well-suited for public and high-traffic spaces.

- Long-Lasting & Low Maintenance: Enjoy reliable performance for years with minimal upkeep. FRP I beams resist fading, cracking, warping, and wear, even in harsh Australian sunlight and challenging conditions.

- Versatile Applications: Ideal for load-bearing structures, frames, supports, safety barriers, and industrial linings—across mining, marine, construction, and infrastructure projects wherever a strong, dependable I beam is essential.

I Beam Profile Options

FRP I Beams are available in a variety of thicknesses, widths, and lengths to suit your project’s specific requirements. These include:

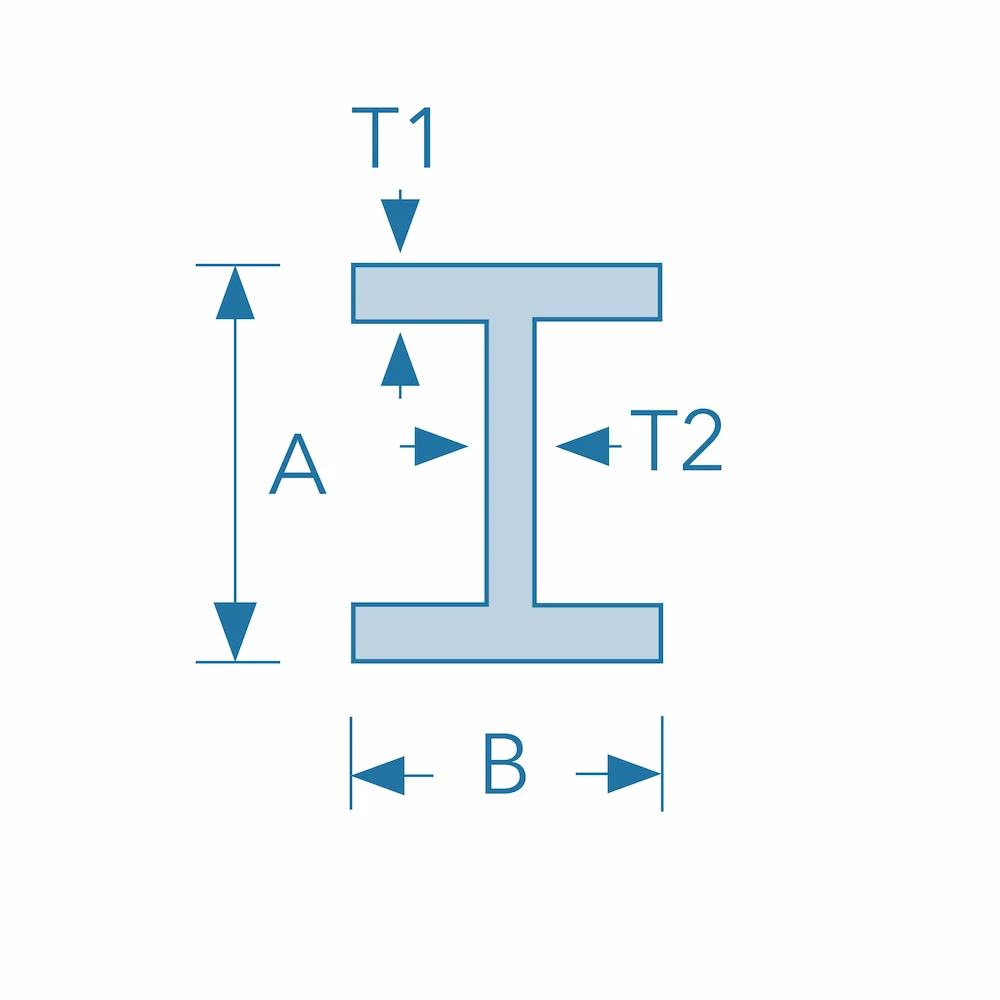

| Profile | Type | Dimension (mm) | Weight |

|---|---|---|---|

| I Beam | A x B x T1 x T2 | (kg/m) | |

| IB | IB32x15x6.4×4.0 | 32 x 15 x 6.4 x 4.0 | 0.51 |

| IB | IB38x30x3.0x3.0 | 38 x 30 x 3.0 x 3.0 | 0.53 |

| IB | IB102x50x6.4×6.4 | 102 x 50 x 6.4 x 6.4 | 2.40 |

| IB | IB102x50x8.0x8.0 | 102 x 50 x 8.0 x 8.0 | 3.00 |

| IB | IB140x70x6.35×6.35 | 140 x 70 x 6.35 x 6.35 | 3.30 |

| IB | IB152x76x6.4×6.4 | 152 x 76 x 6.4 x 6.4 | 5.32 |

| IB | IB152x127x9.5×9.5 | 152 x 127 x 9.5 x 9.5 | 7.10 |

| IB | IB152x127x12.7×12.7 | 152 x 125 x 12.7 x 12.7 | 9.20 |

| IB | IB180x45x9.0x12.0 | 180 x 45 x 9.0 x 12.0 | 5.40 |

| IB | IB203x102x9.5×9.5 | 203 x 102 x 9.5 x 9.5 | 7.20 |

| IB | IB203x102x12.7×12.7 | 203 x 102 x 12.7 x 12.7 | 9.50 |

| IB | IB240x120x12.0x12.0 | 240 x 129 x 12.0 x 12.0 | 10.50 |

| IB | IB254x127x9.5×9.5 | 254 x 127 x 9.5 x 9.5 | 9.00 |

| IB | IB254x127x12.7×12.7 | 254 x 127 x 12.7 x 12.7 | 11.90 |

| IB | IB305x152x9.5×9.5 | 305 x 152 x 9.5 x 9.5 | 10.74 |

| IB | IB305x152x12.7×12.7 | 305 x 152 x 12.7 x 12.7 | 14.30 |

Applications

FRP I Beam sections are highly versatile, suitable for a broad range of applications across multiple industries.

- Mining: Used for structural supports, framing, and protective barriers in areas with frequent movement or exposure to corrosive substances, FRP I beams retain outstanding durability and safety.

- Marine: Perfect for wharves, platforms, and walkways exposed to saltwater and weather, providing robust, reliable support and safe transitions in slippery or busy environments.

- Construction & Infrastructure: Preferred for lightweight yet resilient structural frameworks, safety barriers, and interfaces on floors and walls. The I beam profile enhances stability and delivers a professional finish.

- Industrial & Utility Sites: Frequently specified for chemical plants, water treatment facilities, and electrical substations—offering both insulating properties and safer structural detailing in tough or hazardous conditions.

Specifications

Custom sizing is available upon request, and with advanced CNC fabrication, GRP Australia ensures every I beam is manufactured to your exact needs for a flawless fit. All products meet Australian standards and undergo rigorous testing to ensure safety, durability, and top performance.

Why Choose FRP I Beams?

If your project is in a hazardous or high-traffic environment, requires weight reduction without sacrificing strength, or needs a durable, low-maintenance solution that enhances user safety and aesthetics, our FRP I Beam Structural Sections are a standout choice. These solutions are specifically designed for Australian conditions and are supported by local expertise.