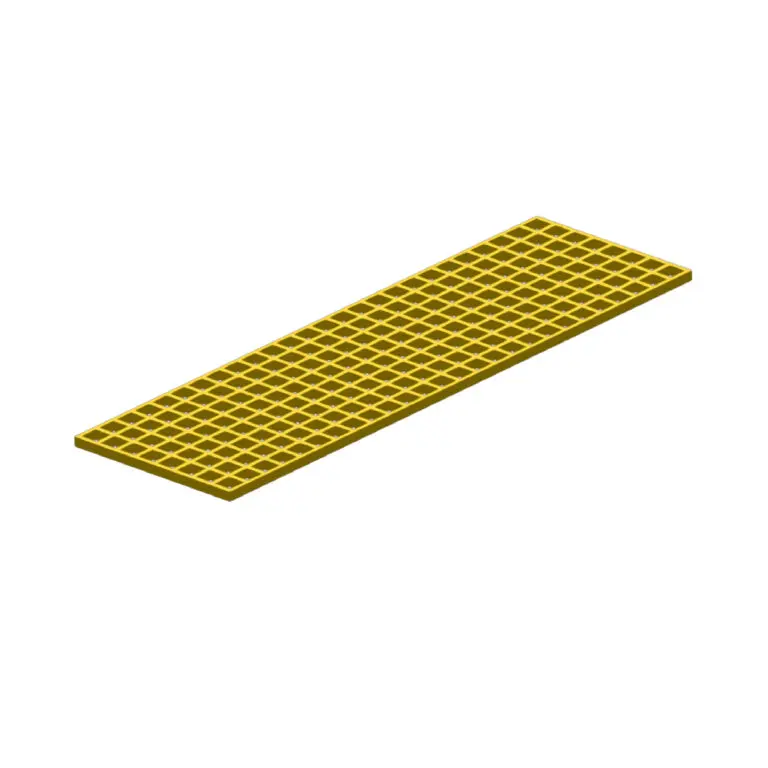

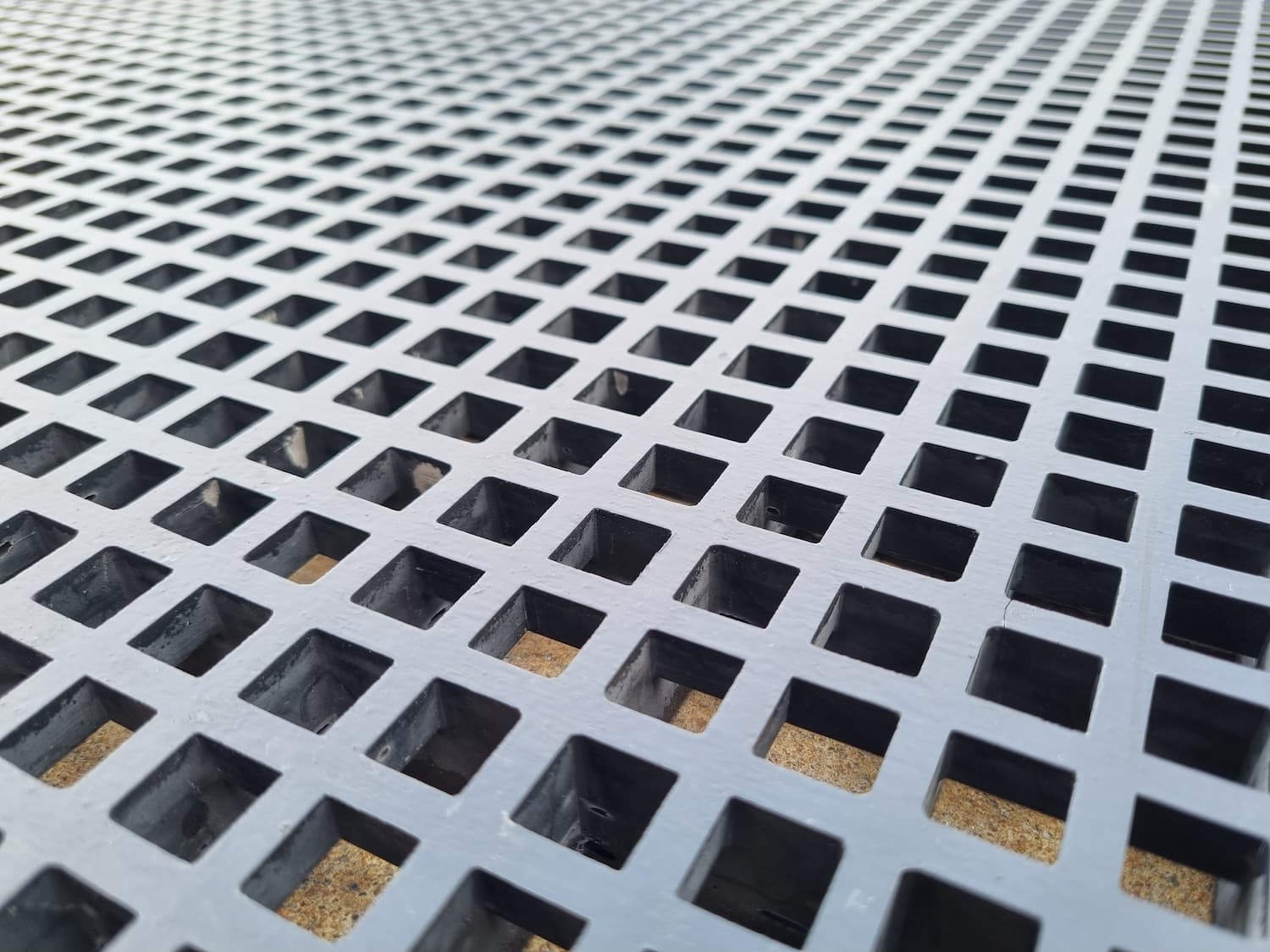

FRP Grating and Treads

Categories

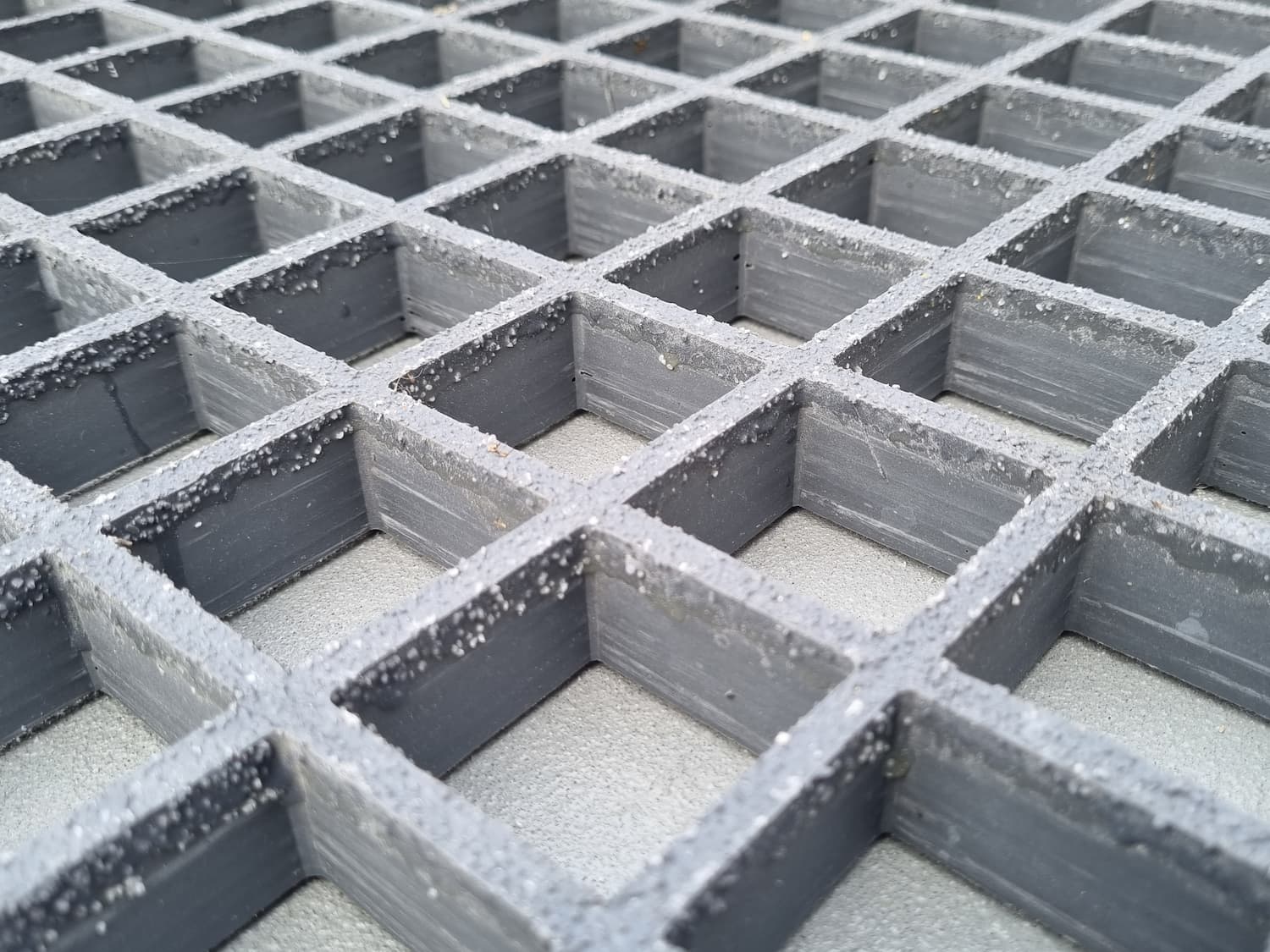

FRP grating and treads are high-performance, durable solutions designed for both industrial and commercial applications. Manufactured using a heated open mould system, our grating features a seamless, one-piece construction that ensures lasting structural integrity.

With features like corrosion resistance, non-conductivity, and a gritted surface for excellent slip resistance, FRP grating and treads are an ideal alternative to traditional materials such as steel and wood. Available in various colours, resin types, and sizes, they offer unmatched versatility and minimal maintenance requirements.

Where Can You Use FRP Grating and Treads?

FRP grating and treads are suitable for a wide variety of environments and industries, providing reliable and long-lasting performance. Common applications include:

Mining and Industrial Facilities

Durable walkways and platforms for heavy-duty environments.

Recommended Grading: Industrial grading

Marine Infrastructure

Corrosion-resistant covers for docks, piers, and offshore platforms.

Recommended Grading: Mini Mesh

Public Spaces

Long-lasting infrastructure for walkways, parks, and communal areas.

Recommended Grading: Heel Guard and Mini Mesh

Residential and Outdoor Spaces

Stylish solutions for pool decking, garden beds, shade structures, and more.

Recommended Grading: Heel Guard and Mini Mesh

Chemical and Water Treatment Plants

Anti-corrosive grating for platforms and drainage systems in chemical-exposed facilities.

Recommended Grading: Industrial grading

Rural and Agricultural Sectors

Hardwearing infrastructure for cattle ramps, loading ramps, and aqua farms.

Recommended Grading: Agri Mesh and Mini Mesh

Technical Specifications

FRP grating and treads demonstrate superior material properties and design capabilities. Here’s why our grating and treads make them a game-changer.

Fire Rating Properties

Offers excellent fire rating properties, including resistance to ignition and low flame spread, making it suitable for use in environments where fire safety is a priority.

Material Construction

Manufactured with thermosetting resin combined with glass-reinforced fibres for maximum strength.

Grating Thickness

Available in multiple thicknesses for different load and span needs.

High Corrosion Resistance

Designed to withstand harsh environments, including chemical and marine exposure.

Safety Compliance

Compliant with industry safety standards for non-slip and fire retardancy.

Non-Conductive

Safe to use in electrical and power plant installations.

Customise FRP Grating and Treads to Your Project

FRP grating and treads are designed with flexibility in mind. From size to style, you can customise them to fit your exact requirements. Here’s how you can make them uniquely yours.

Resin Types: Choose from isophthalic or vinyl ester depending on the corrosiveness of the environment.

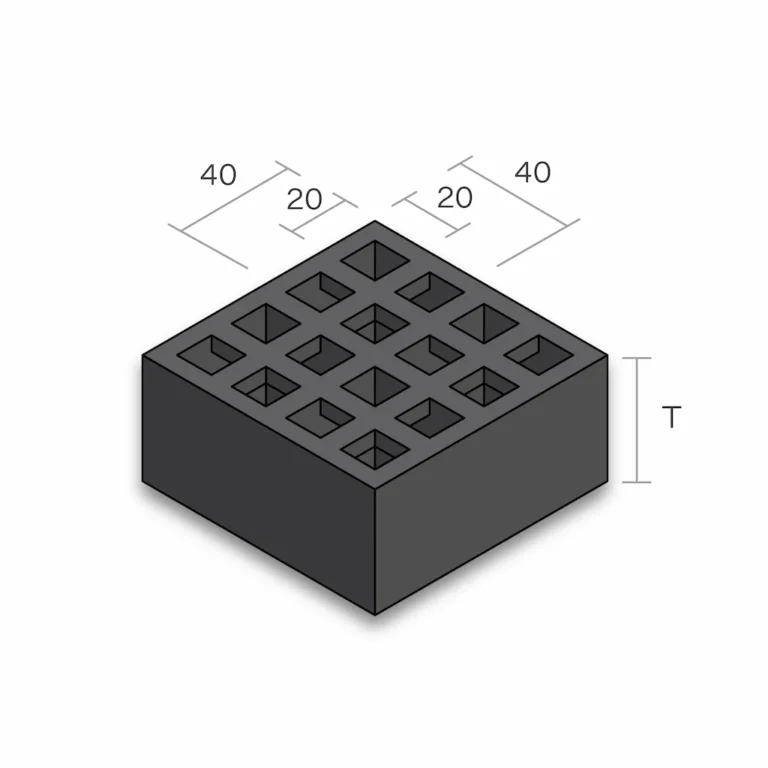

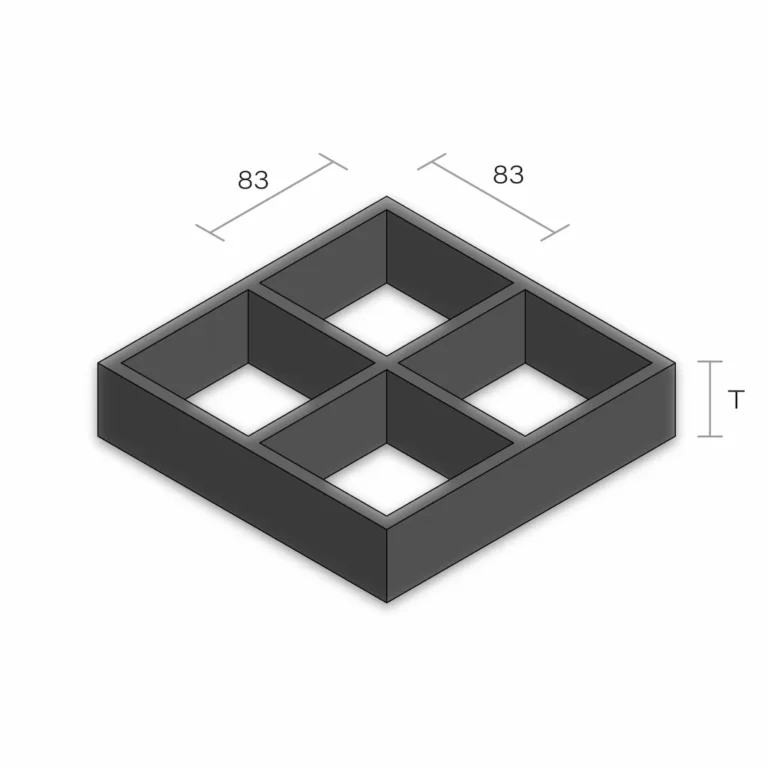

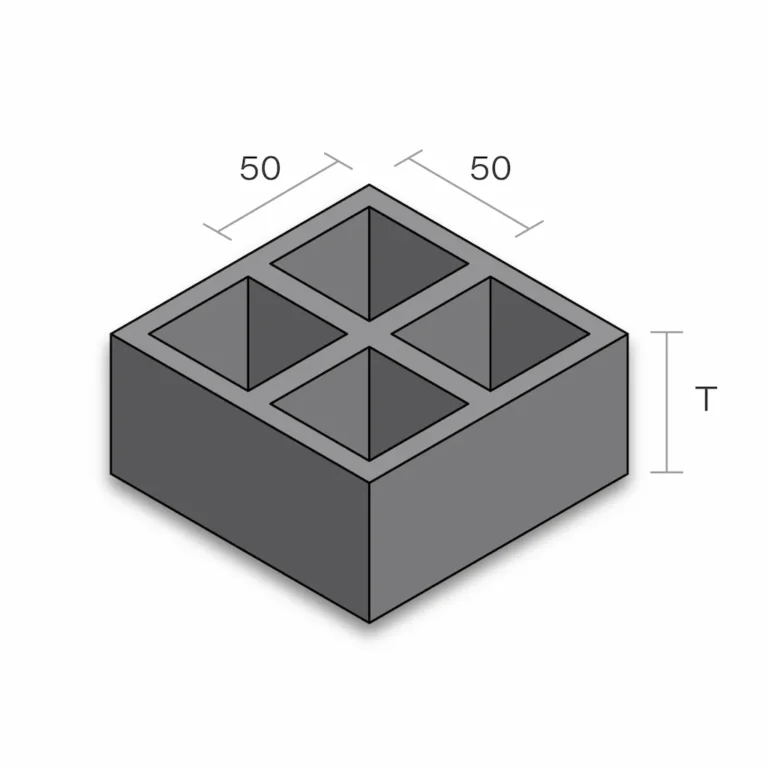

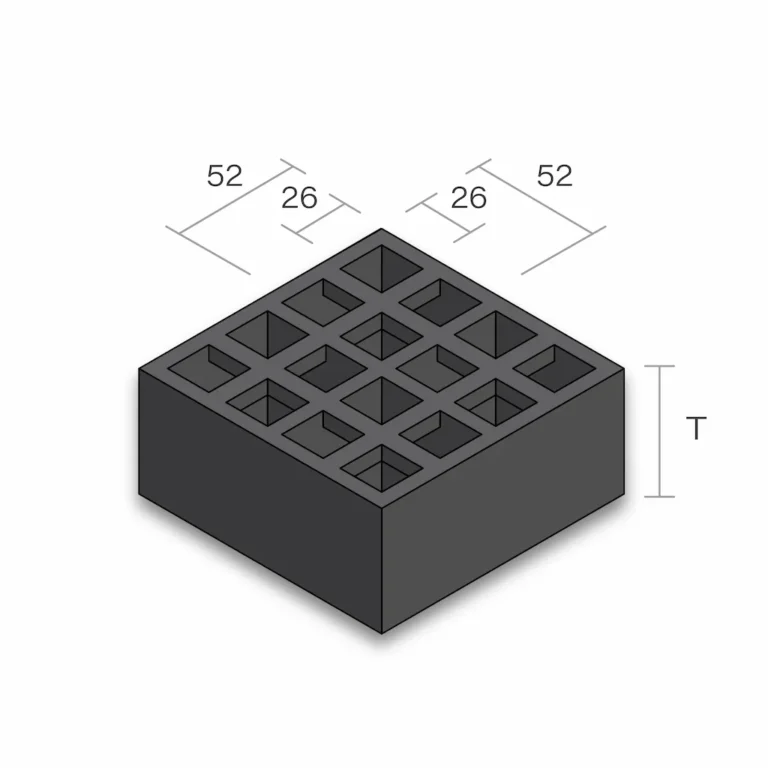

Sizes and Mesh Configurations:

- 13 x 13 Heel Guard

- 19 x 19 Mini Mesh

- 38 x 38 Standard

- And more!

Fabrication Capabilities: Ability to prefabricate moulded grading to size for ease of installation.

CNC Capabilities: Ability to achieve more complex & bespoke designs – dxf files required by customer

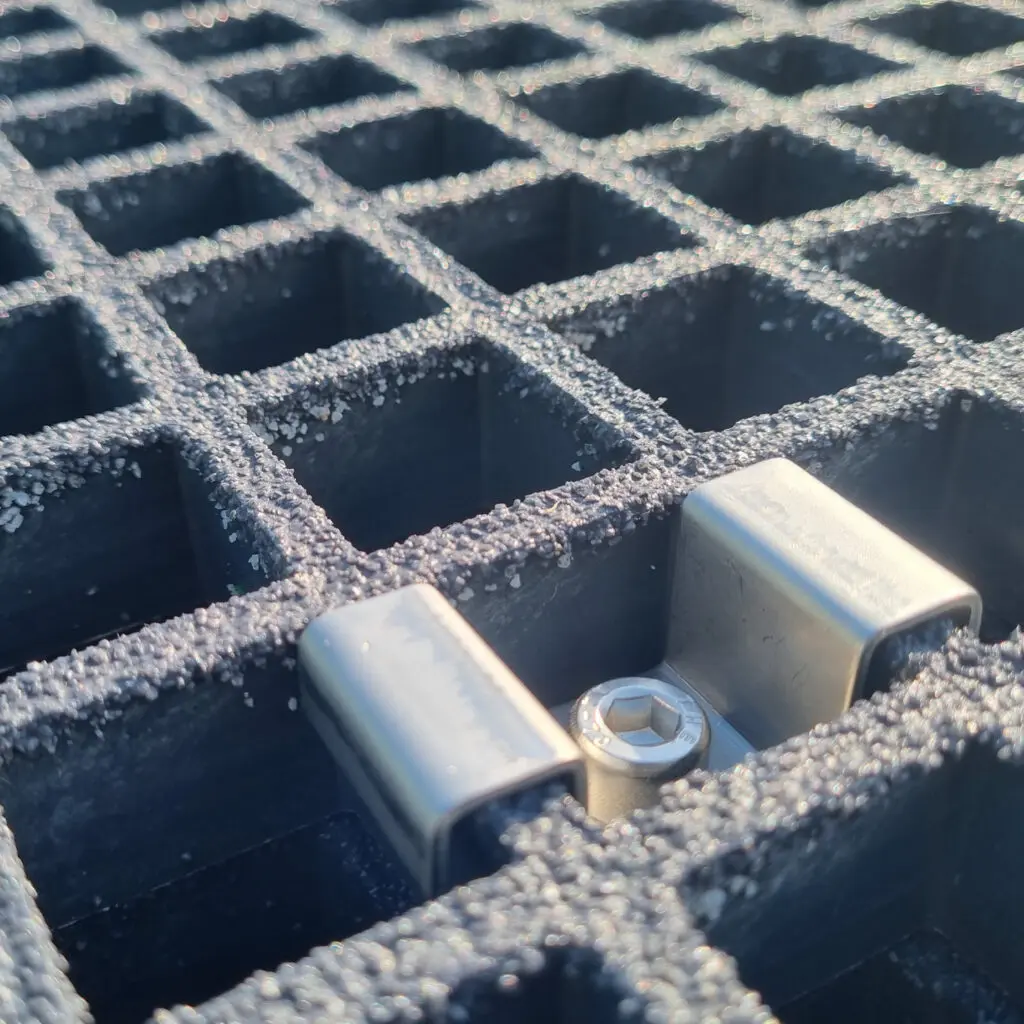

Hardware: Complementary 316ss Clips & Brackets to secure grating in challenging conditions Complementary stainless-steel clips and brackets for secure mounting in challenging conditions.

Surface Look of the Grating

Gritted, flat, and solid top surfaces provide excellent traction, even in wet or oily conditions. These surface options ensure safety and adaptability across various environments, making them ideal for industrial, commercial, and residential applications.

Gritted Surface

Offers superior slip resistance, perfect for hazardous or high-traffic areas.

Flat Surface

Provides a smooth finish for applications requiring a clean and polished look.

Solid Top Surface

Ensures maximum coverage and safety, especially in environments with small debris or liquids.

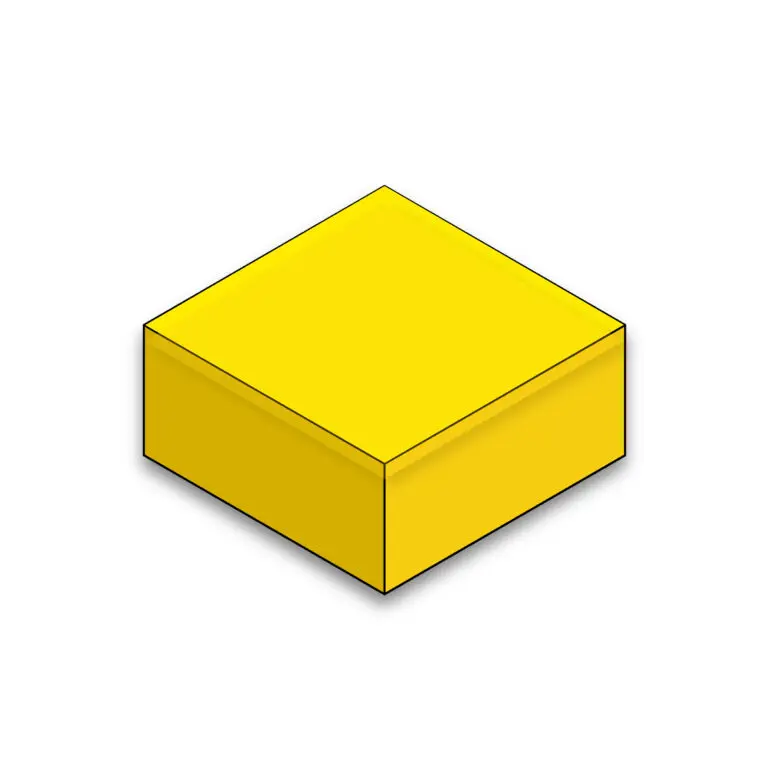

Colour Variations

FRP grating and treads are available in a wide range of standard colours, with custom options to match your aesthetic or branding needs. Whether you’re looking for a bold statement or a subtle, professional finish, we’ve got you covered.

Standard Colours

Choose from a palette of popular colours designed to suit most applications.

Custom Options

Grating & Treads can be custom manufactured to any RAL Colour to align with your brand identity or project requirements. Custom colours have a lead time of 10-12 weeks.

Benefits

Benefits of FRP Grating and Treads

FRP grating and treads deliver superior performance and durability in a range of applications. Key benefits include:

Corrosion Resistance

Ensures longevity in environments exposed to chemicals, salt, and moisture.

Non-Conductive

Safe to use in electrical and power plant installations.

Slip Resistance

Gritted surfaces provide excellent traction, enhancing safety in hazardous areas.

Lightweight and Strong

Simplifies installation while maintaining structural strength.

Low Maintenance

Requires minimal upkeep, lowering long-term operational costs.

Long Lasting

Designed for a high life expectancy, adaptable to various applications.

Resources

FRP Grating and Treads Downloads

At GRP Australia, we provide you with the resources and support necessary to ensure the successful installation and optimal performance of FRP grating and treads. Explore our resources for more information.

FAQs

What are the advantages of FRP moulded grating compared to traditional materials?

FRP moulded grating offers high corrosion resistance, lightweight design, and excellent strength-to-weight ratio. It is non-conductive, slip-resistant, and requires minimal maintenance, making it ideal for harsh environments.

Can FRP moulded grating be customized to specific dimensions?

Yes, FRP moulded grating can be tailored to meet specific project requirements, including various sizes, thicknesses, and panel configurations. Customizations can also include colour and surface finish however these involve a leadtime of 10-12 weeks.

What is the typical lifespan of FRP moulded grating?

FRP moulded grating is highly durable and typically lasts for decades, even in corrosive environments. Its resistance to chemicals and UV exposure ensures long-term performance.

What are the best tools to fabricate FRP moulded grating?

The best tools for fabricating FRP moulded grating include diamond-coated saw blades for clean and precise cuts, carbide-tipped drill bits for creating holes, and grinders for smooth edge finishing. Using these specialized tools ensures accuracy and maintains the structural integrity of the material.

Is FRP moulded grating suitable for outdoor applications?

Absolutely. FRP moulded grating is designed to withstand exposure to ultraviolet (UV) rays, moisture, and a wide range of weather conditions, making it an excellent choice for outdoor environments.

How does FRP moulded grating perform in chemical plants or marine environments?

FRP moulded grating exhibits outstanding resistance to a broad spectrum of chemicals, including acids, alkalis, and solvents. Its non-corrosive nature ensures longevity and reliability even in highly aggressive or saline atmospheres.

What maintenance is required for FRP moulded grating?

Maintenance requirements are minimal. Periodic cleaning with water or mild detergents is typically sufficient to keep the grating in optimal condition. Routine visual inspections are recommended to ensure long-term safety and performance.

Can FRP moulded grating be used in electrical or food processing facilities?

Yes, FRP moulded grating is non-conductive, making it ideal for applications where electrical safety is crucial. Additionally, its hygienic, easy-to-clean surface and resistance to bacterial growth make it suitable for use in food processing or preparation areas.

What are the standard colours and finishes available for FRP moulded grating?

FRP 38×38 moulded grating typically comes in grey, yellow, and green. Other grating types are available in Black Grey and Light Grey, with grit-top or smooth finishes for slip resistance and aesthetics. Custom colours and finishes are available upon request.

Is FRP moulded grating environmentally friendly?

FRP moulded grating is a durable, long-lasting product that reduces the need for frequent replacements, thereby minimising waste. Many manufacturers also offer recyclable options or use sustainable production practices.

Case Studies

Discover how our FRP grating and treads have transformed projects across various industries. From industrial facilities to public spaces, our innovative solutions deliver unmatched performance, safety, and durability. Explore these real-world applications to see how we’ve helped clients overcome challenges and achieve their goals.

Mining and Industrial Facilities

Marine Infrastructure

Public Spaces

Residential and Outdoor Spaces

Chemical and Water Treatment Plants

Rural and Agricultural Sectors

Transform Your Project With Anti-Slip, Durable Grating and Treads

Our FRP grating and treads are engineered for unmatched performance, durability, and safety. Contact our team today to schedule a consultation, receive a tailored quote, or explore our innovative product range.