FRP Grating & Treads

Categories

FRP Grating & Treads

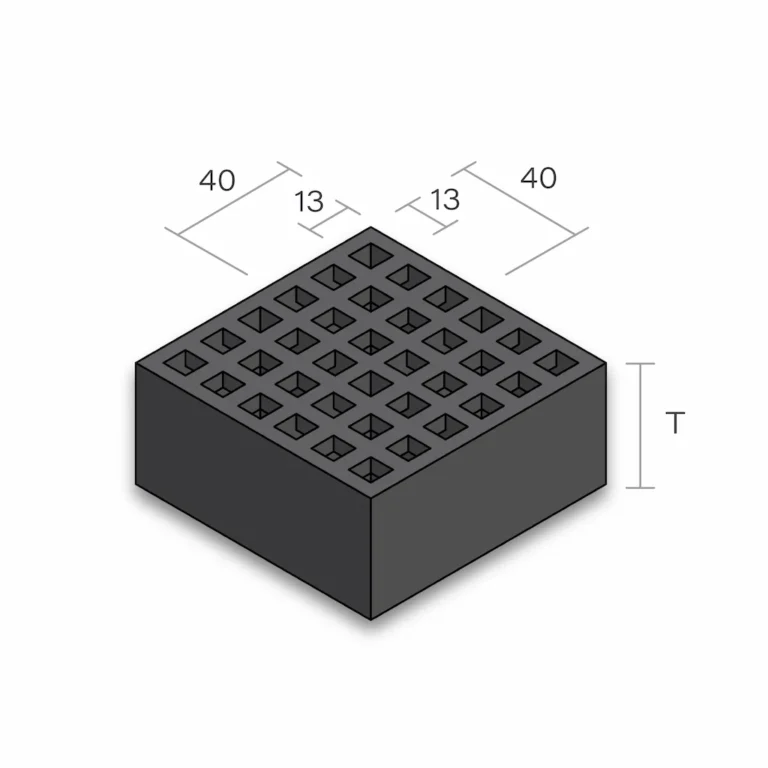

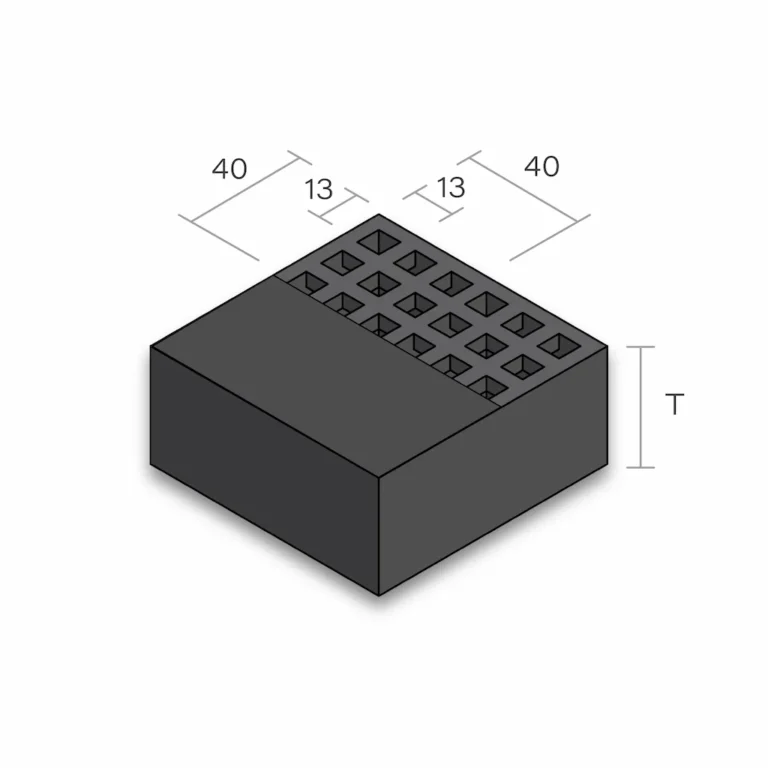

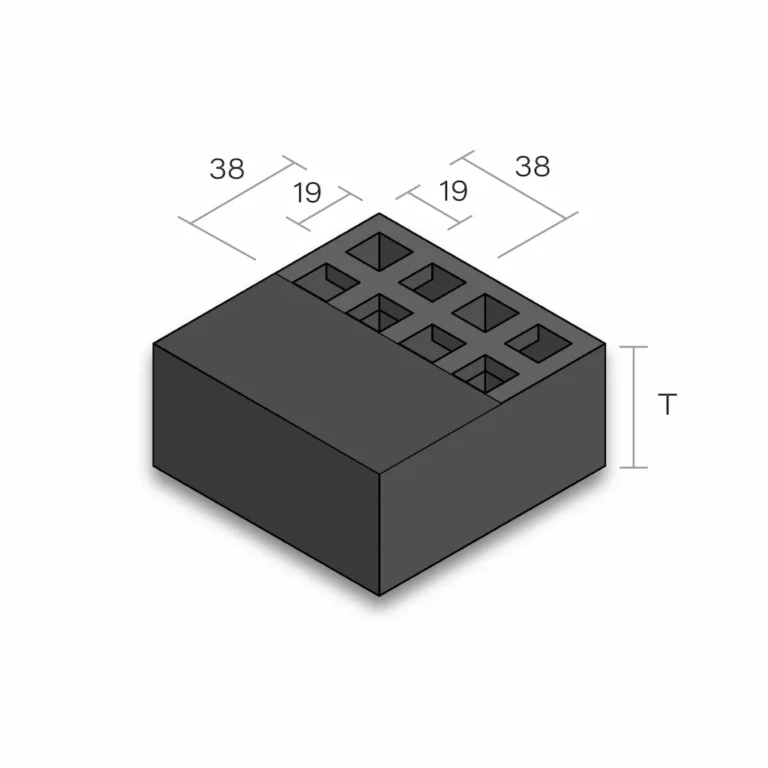

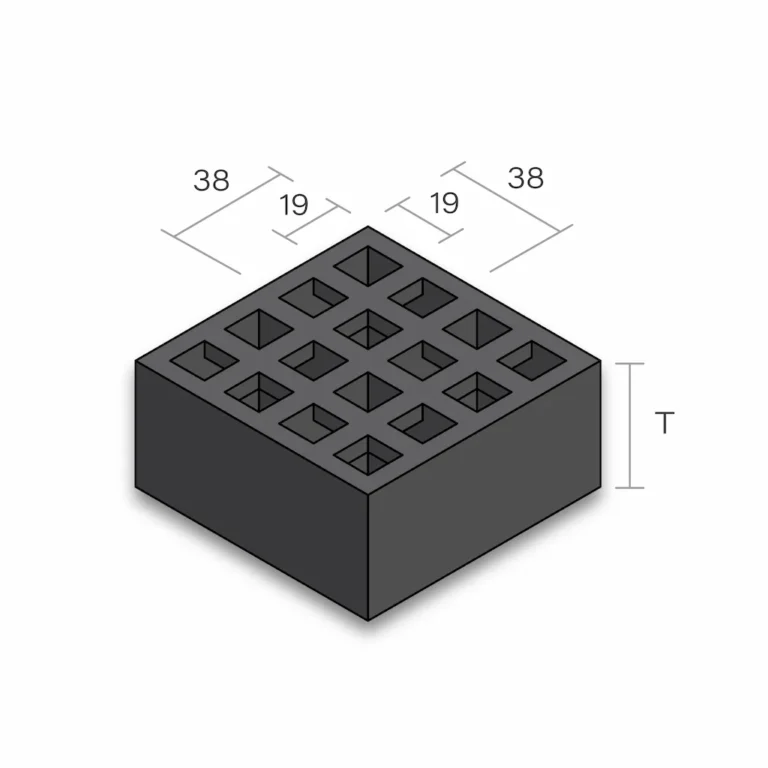

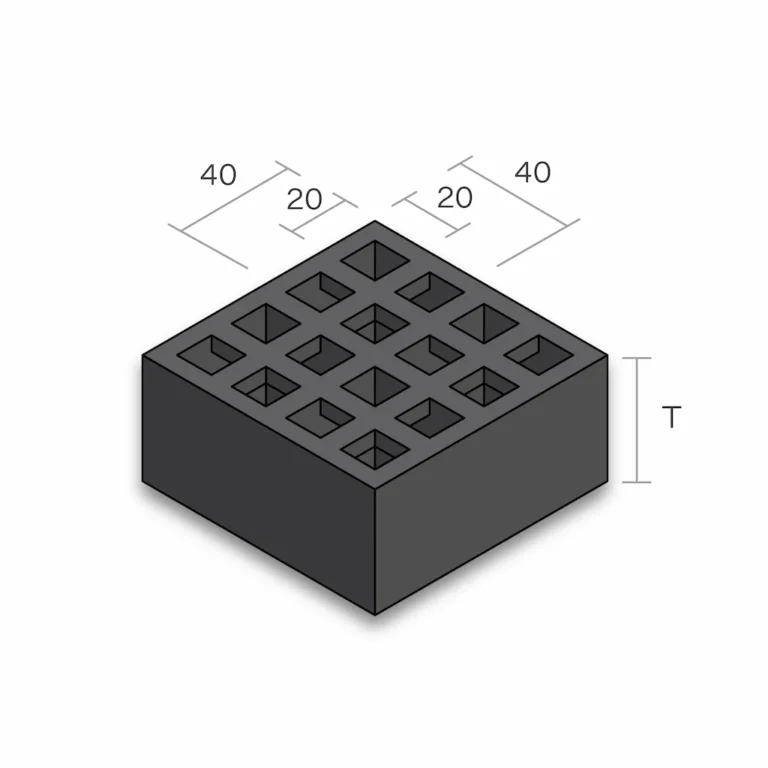

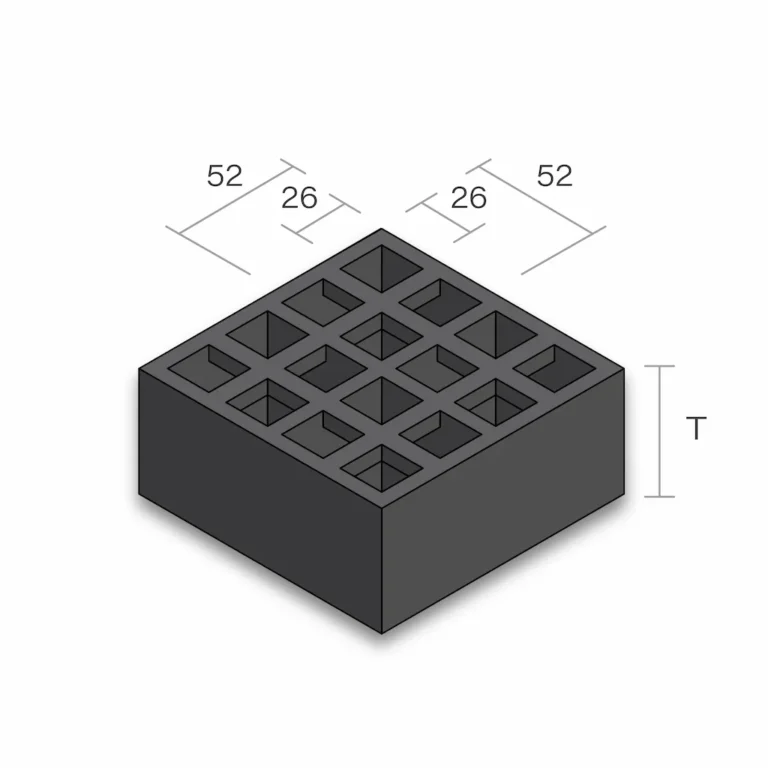

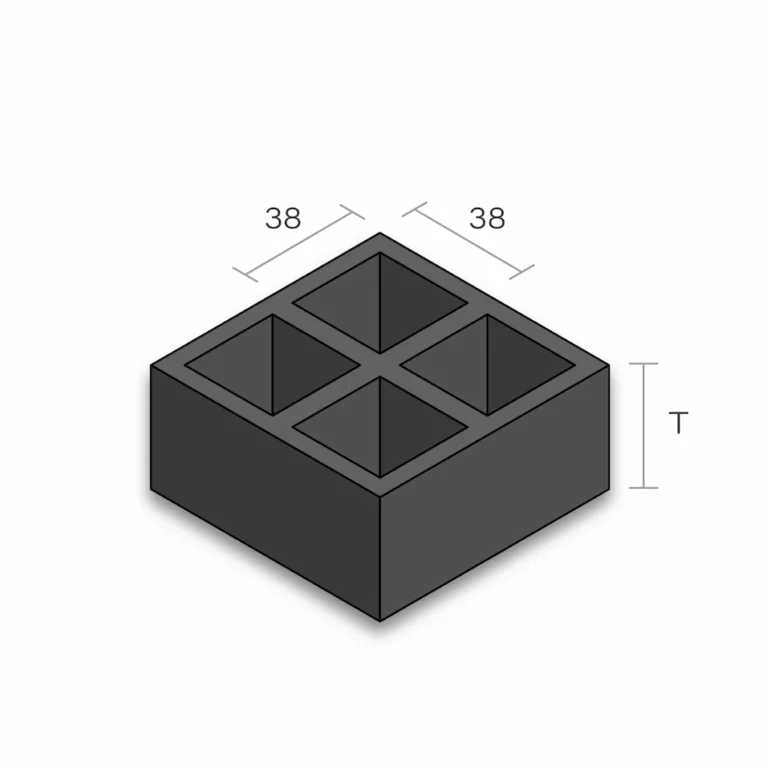

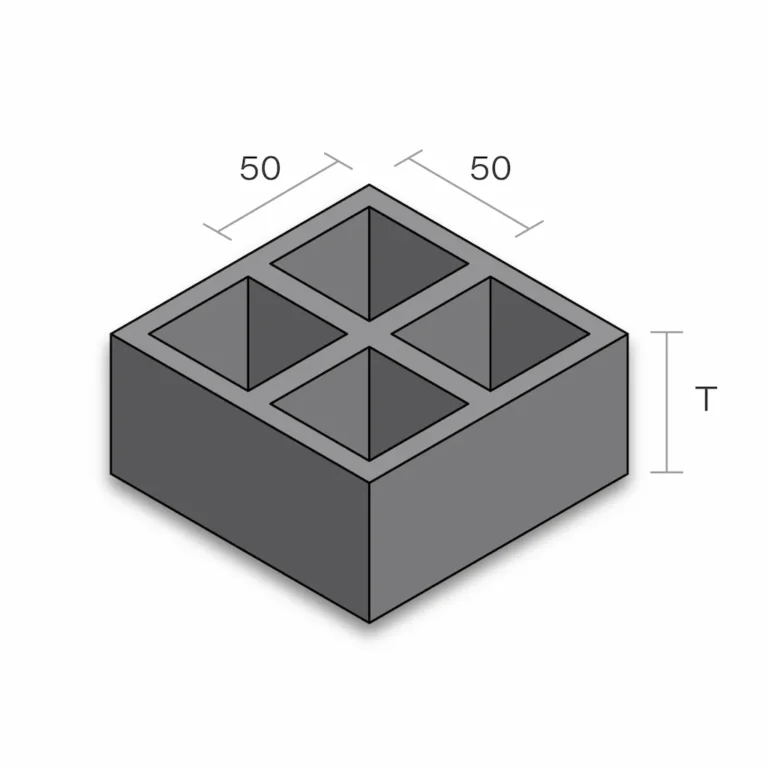

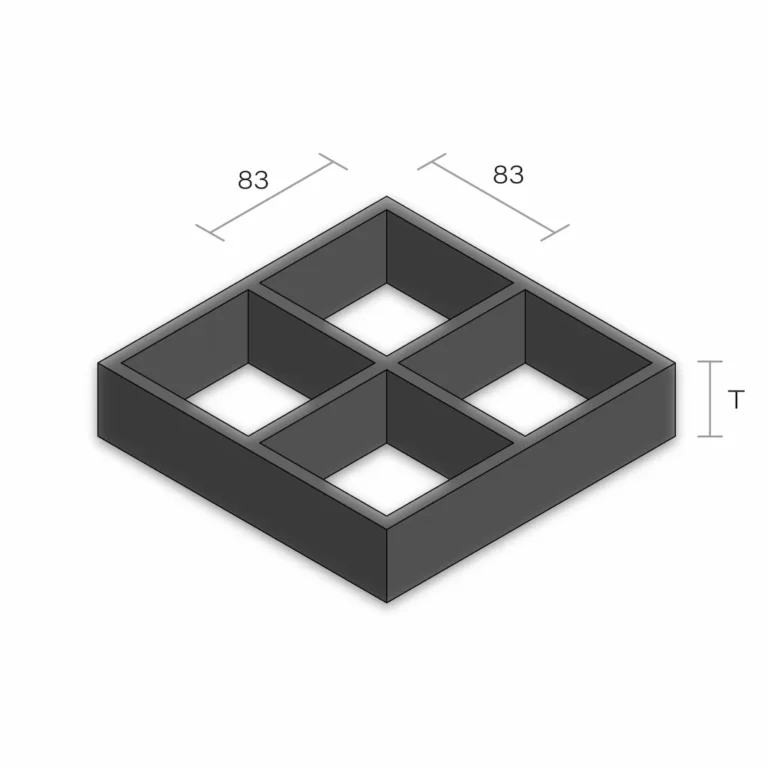

The FRP grating is manufactured using an open, heated mould system resulting in an integral one-piece construction. This grating offers a long service life, is maintenance free, non-conductive, anti-corrosive, easy to install and available in a range of colours and resin types. The grating can be supplied with a gritted surface which offers excellent traction in all weather conditions. A broad range of industries including mining, chemical plants, electrical and marine are using this product as an ideal and cost-effective alternative to traditional materials. Additionally, GRP Australia has a range of accessories in stainless steel for ease of installation and durability in harsh conditions.

See FRP Grating and Treads in Action

Residential & Public Spaces

Marine Applications

Mining and Industrial Applications

Resources

FAQs

What are the advantages of FRP moulded grating compared to traditional materials?

FRP moulded grating offers high corrosion resistance, lightweight design, and excellent strength-to-weight ratio. It is non-conductive, slip-resistant, and requires minimal maintenance, making it ideal for harsh environments.

Can FRP moulded grating be customized to specific dimensions?

Yes, FRP moulded grating can be tailored to meet specific project requirements, including various sizes, thicknesses, and panel configurations. Customizations can also include colour and surface finish however these involve a leadtime of 10-12 weeks.

What is the typical lifespan of FRP moulded grating?

FRP moulded grating is highly durable and typically lasts for decades, even in corrosive environments. Its resistance to chemicals and UV exposure ensures long-term performance.

What are the best tools to fabricate FRP moulded grating?

The best tools for fabricating FRP moulded grating include diamond-coated saw blades for clean and precise cuts, carbide-tipped drill bits for creating holes, and grinders for smooth edge finishing. Using these specialized tools ensures accuracy and maintains the structural integrity of the material.

Is FRP moulded grating suitable for outdoor applications?

Absolutely. FRP moulded grating is designed to withstand exposure to ultraviolet (UV) rays, moisture, and a wide range of weather conditions, making it an excellent choice for outdoor environments.

How does FRP moulded grating perform in chemical plants or marine environments?

FRP moulded grating exhibits outstanding resistance to a broad spectrum of chemicals, including acids, alkalis, and solvents. Its non-corrosive nature ensures longevity and reliability even in highly aggressive or saline atmospheres.

What maintenance is required for FRP moulded grating?

Maintenance requirements are minimal. Periodic cleaning with water or mild detergents is typically sufficient to keep the grating in optimal condition. Routine visual inspections are recommended to ensure long-term safety and performance.

Can FRP moulded grating be used in electrical or food processing facilities?

Yes, FRP moulded grating is non-conductive, making it ideal for applications where electrical safety is crucial. Additionally, its hygienic, easy-to-clean surface and resistance to bacterial growth make it suitable for use in food processing or preparation areas.

What are the standard colours and finishes available for FRP moulded grating?

FRP 38×38 moulded grating typically comes in grey, yellow, and green. Other grating types are available in Black Grey and Light Grey, with grit-top or smooth finishes for slip resistance and aesthetics. Custom colours and finishes are available upon request.

Is FRP moulded grating environmentally friendly?

FRP moulded grating is a durable, long-lasting product that reduces the need for frequent replacements, thereby minimising waste. Many manufacturers also offer recyclable options or use sustainable production practices.

Contact GRP Today

Discover how GRP Australia can bring your ideas to life with cutting-edge FRP design and engineering tailored to your needs.

Contact us today to explore what’s possible!