Challenging environments demand innovative solutions. In construction, exposed, demanding, or corrosive conditions can quickly reveal the limitations of traditional building materials, often leading to frequent maintenance and costly repairs. That’s where Fibreglass Reinforced Plastic (FRP) shines. This high-strength, corrosion-resistant composite material is specifically designed to thrive in tough environments, offering a reliable and long-lasting alternative.

In this guide, we’ll uncover how FRP excels in demanding conditions and highlight the key industries that benefit from its exceptional durability and performance.

Superior Strength of FRP

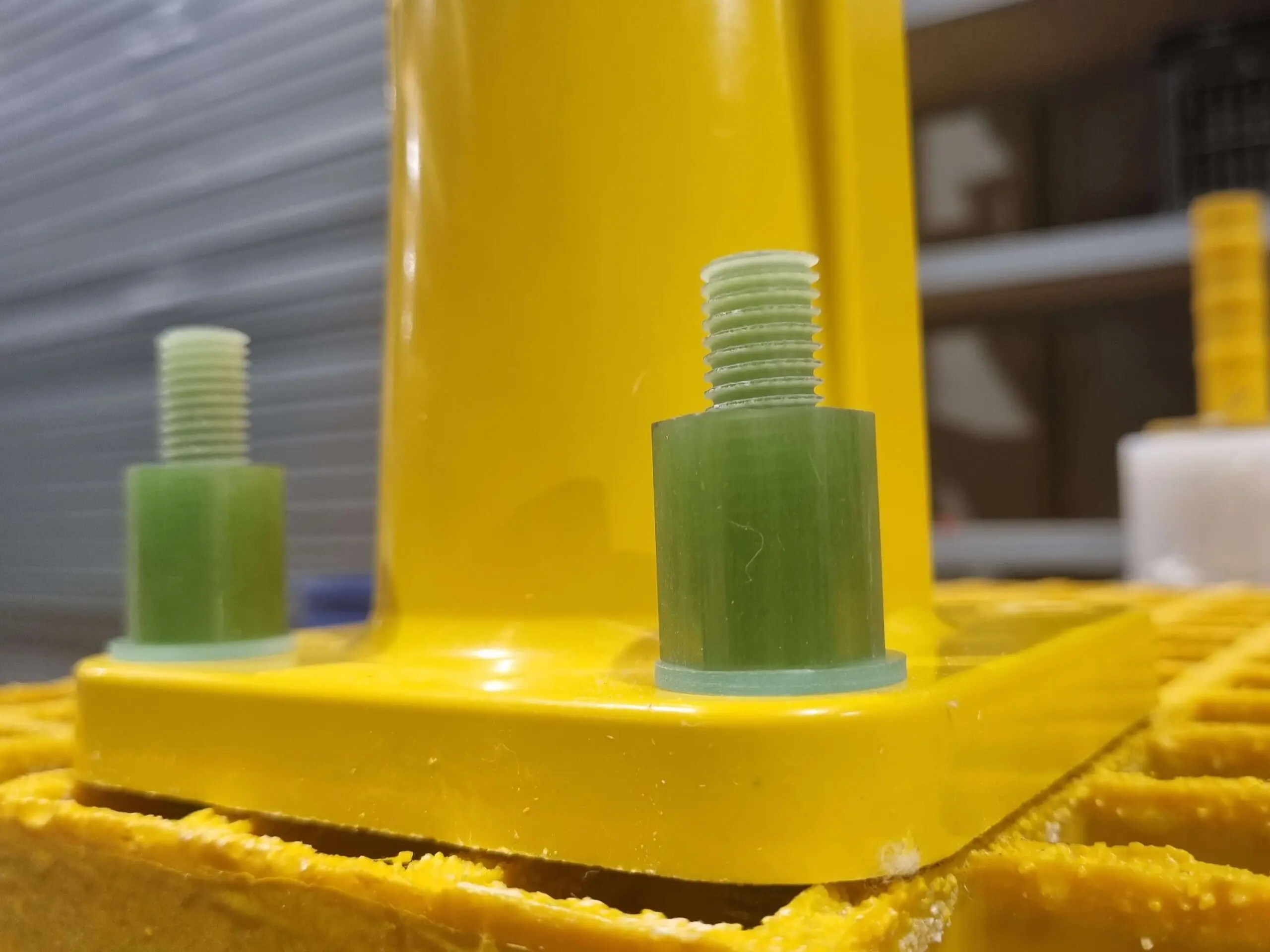

Fibreglass reinforced polymer (FRP) is known for its impressive strength-to-weight ratio, offering high durability without added hassle. This allows for safer, more efficient installation and maintenance, requiring fewer hands to lift the load. Moreover, its lightweight nature allows for cheaper freight costs, making it a smart economic choice for large projects.

FRP is also highly resistant to corrosion from chemicals, weathering, and saltwater, ensuring it maintains strength and integrity for longer periods of time, even in harsh conditions. Whether installing FRP flooring on a pontoon or FRP handrails for industrial equipment, you can trust that this material will deliver lasting safety, durability, and reliability.

Top Industry Applications for FRP

The lightweight, durable, and corrosion-resistant design of fibreglass reinforced polymer (FRP) makes it the ideal choice for demanding environments and applications. This innovative material is revolutionising how builders and industries face challenges, enhancing safety, reducing maintenance costs, and extending the lifespan of critical infrastructure.

Explore some of the top industries where FRP is making the biggest impact, including:

Mine Sites

Mine sites are notorious for their harsh conditions and exposure to chemicals and extreme weather, requiring materials just as robust as the environment. FRP is perfect for delivering safe, reliable, and easy-to-install solutions, designed to withstand harsh mining environments.

Some of the most common applications for FRP in the mining sector include:

- FRP Flooring: provides safe walkways throughout mine sites to working stations, equipment, or amenities,

- FRP Stairs and Handrails: ensure stable, non-slip entry to elevated equipment and surfaces.

Marine Environments

Saltwater, high humidity, and frequent weather events make working in marine environments hazardous and challenging. However, due to its non-corrosive design, FRP is the perfect fit for constructions on, near or around the water.

FRP moulding gratings, flooring, and handrail systems are frequently used to ensure safety and longevity for:

- Jetties,

- Pontoons,

- Piers,

- Bridges,

- Docks,

- Boat Ramps,

- Look Outs.

Heavy Industrial Settings

Heavy industrial settings often work with aggressive chemicals, heavy machinery, and equipment that can stress, corrode, and damage traditional building materials such as concrete, steel, or timber. FRP, on the other hand, is engineered to withstand corrosive chemicals, water and heavy loads, delivering safe, durable, and reliable access solutions. Additionally, FRP is non-conductive and non-magnetic, offering added safety and benefits for sensitive instruments and high-voltage installations.

Heavy industrial settings often utilise FRP for:

- Electrically insulated perimeter fencing,

- Durable, impact-resistant flooring for walkways,

- Non-slip, secure stair treads and handrails.

Railway Infrastructure

Railway infrastructure acts as the backbone of Australia’s freight and passenger transport, playing a critical role in supply chains and connectivity. Withstanding daily loads, constant use, and harsh environmental conditions requires tough solutions; FRP offers just that.

Built to withstand Australia’s harsh climate, FRP products are ideal for exposed, outdoor and high-traffic environments, delivering a lightweight, corrosion-resistant, and low-maintenance solution.

FRP is ideal for a wide range of railway infrastructure projects, including:

- Non-slip stairs for platforms, access points, and maintenance areas.

- Corrosion-resistant safety barriers along walkways, platforms, and bridges.

- Non-conductive perimeter fencing to secure railway tracks and stations.

- Impact-resistant, weatherproof flooring for pedestrian walkways and decks.

- Lightweight, durable bridges, structural elements, and framework.

Public Infrastructure

Many local councils are turning to FRP for new public infrastructure. This shift is driven by the easy installation, minimal maintenance, and superior durability of FRP compared to traditional building materials.

FRP is highly resistant to corrosion, weathering, and general wear and tear from constant foot traffic, making it a cost-effective, long-lasting solution for public infrastructure. It also offers a non-slip finish, providing enhanced public safety.

Local councils are using FRP more often for new infrastructure, such as boardwalks, pedestrian bridges, and public access platforms.

Residential Infrastructure

This is a new sector that has emerged over the last couple of years, as we have seen customers turn to FRP as they are seeking an alternative to traditional decking materials, such as timber, due to the constant maintenance required.

GRP Australia has also recently introduced their Fibreframe system aimed at this sector, which is a decking sub-floor solution designed to achieve the same spans as typically hardwood timber. The benefit is that this system uses FRP for its bearers, joists & posts, leading to a lighter, low-maintenance result. This innovative system features 316ss brackets & ends to make installation easier as well.

The most common residential applications of FRP include:

- Low-maintenance outdoor and pool decks,

- Quality ramps for safe accessibility,

- Non-slip stairs for safe access when wet.

Durable FRP Solutions for Challenging Environments

Whether you need safe, non-slip stair treads with handrails for mine sites or corrosion-resistant flooring for marine settings, fibreglass reinforced plastic offers the perfect solution. This high-strength, resilient composite material is designed to withstand harsh environments and constant use.

Explore our FRP products or contact us today to find out more about this innovative material and order customised solutions for your industry’s challenges.